|

|

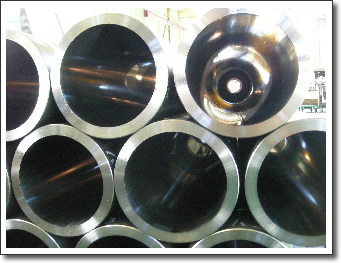

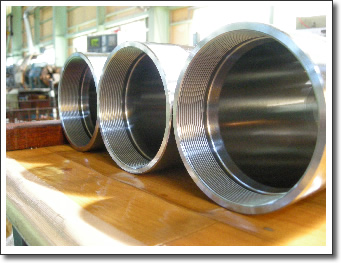

"Capable of Boring Cylinders Of Various Sizes"

Our business is boring cylinders. We provide high quality products, rapidly

and to schedule by controlling manufacturing process.

Moreover, our unique machine is capable of boring cylinders from small

to large and various materials; a thin or unique-shaped bore which is very

difficult to bore using standard methods.

|

| Our experience/technique has been used for hydraulic or pneumatic cylinders,accumulators,

dampers as shock absorbers in structural engineering to reduce susceptibility

of structures to earthquake, and cylinder rolls for circulation. |

|

|

|

|

"Accuracy and Experience"

After

boring, the honing process comes next to smooth an inner surface of a cylinder.

Honing achieves not only smooth surface, but also circularity of the inner

diameter of a cylinder by rotation and straightening of the inner lining by

reciprocating piston.

In

addition, it makes crosshatch pattern internally providing oil reservoir, which

maximises the condition of lubrication.

|

The honing

machine is capable of processing maximum length of 8000mm, inner diameter from

60mm to 700mm.

Our

experienced and skilled technicians finish products with precision working.

These factors enhance the high quality of products. |

|

|

|

|

Cylinders are utilised in many ways. We are capable of making screw threads,

a groove for a slot for O-ring and so on by using Numerical Control (NC)

lathe.

The NC lathe enables steady production in quality and mass production.

We are equipped with a large NC lathe allowing us to process long pipes

and large diameter pipes. |

|

|